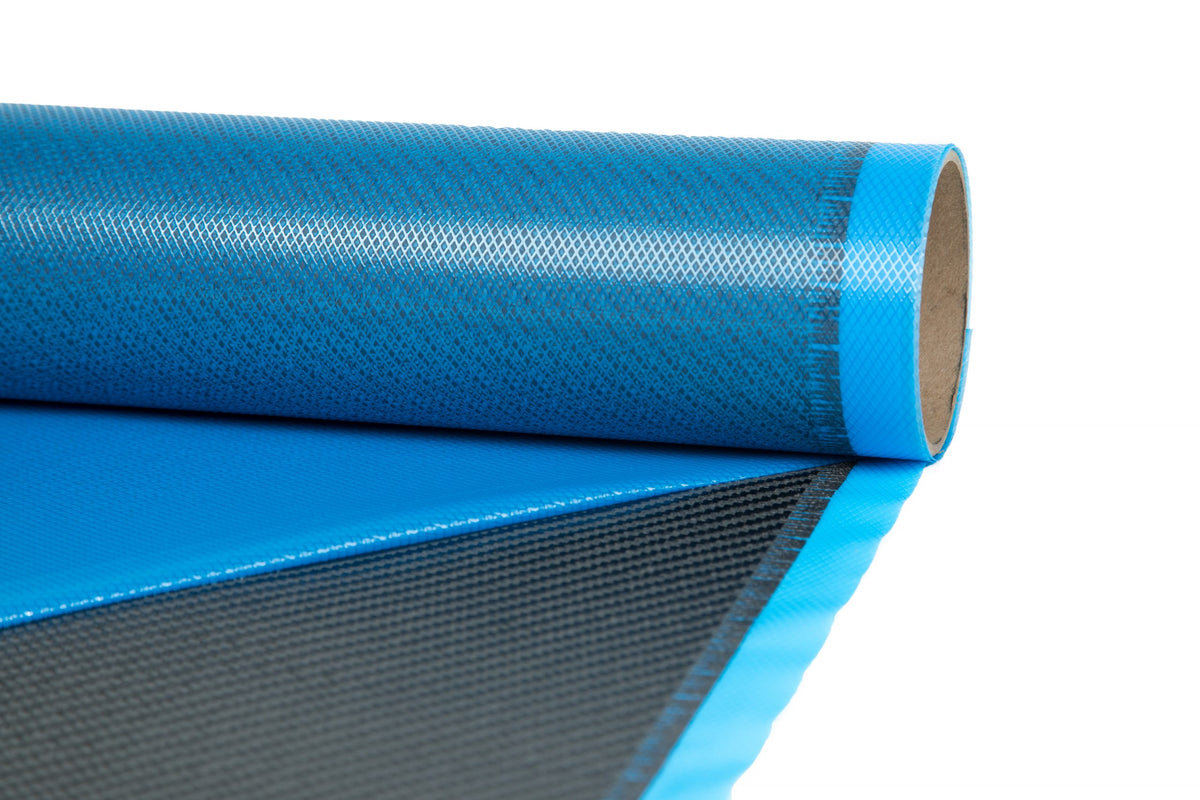

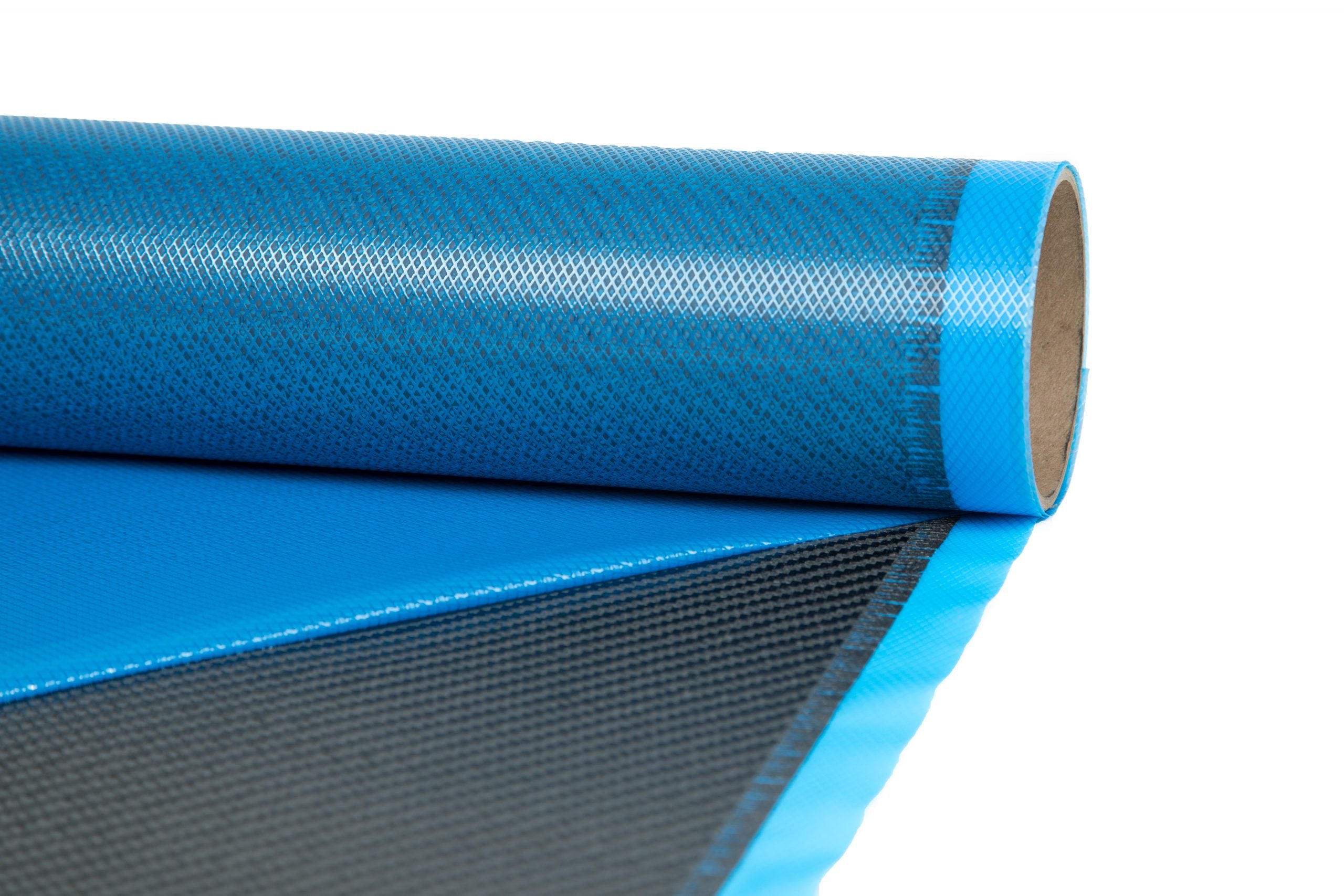

Prepreg Carbon Fibre XC130 210g 2x2 Twill 3k (1250mm) Width

Couldn't load pickup availability

https://www.ebay.co.uk/itm/314715573867

The XC130 prepreg carbon fiber fabric is a premium material designed for high-performance applications, offering exceptional strength, lightweight properties, and a smooth finish. With an areal weight of 210 g/m², it is ideal for lightweight structural components in aerospace, motorsport, and advanced composite industries. The fabric features a prepreg configuration, where the carbon fibers are pre-impregnated with a resin system, ensuring precise fiber-to-resin ratios and consistent quality. At 1250 mm width, the material provides ample coverage, reducing waste and increasing efficiency during layup processes.

SPECIFICATION

Fabric Specification

| Fibre Specifics | Pyrofil TR30S 3k | |

|---|---|---|

| Colour | Black | |

| Fibre Orientation | 0, 90 | |

| Type | Component Prepreg | |

| Resin Matrix | Epoxy | |

| Weave | 2 x 2 Twill | |

| Format | Woven Fabric | |

| Filament Count | 3k | |

| Fibre Type | Carbon Fibre | |

| Ends | 5 | cm |

| Picks | 5 | cm |

Fibre Properties

| Width | 1250 | mm |

|---|---|---|

| Min Cure Temp | 80 | °C |

| Max Cure Temp | 120 | °C |

| Max Service Temp | 130 | °C |

| Filament Diameter | 7 | µm |

| Out-life (at 20°C) | 30 | Days |

| Freezer-life (at -18°C) | 12 | Months |

| UV Resistance | Good |

Weight and Dimensions

| Consolidated Thickness | 0.25 | mm |

|---|---|---|

| Areal Weight | 210 | g/m² |

| Resin Weight | 42 | % |

Typical Laminate Properties

| Brand | XPREG | |

|---|---|---|

| Tensile Strength | 645 | MPa |

| Tensile Modulus | 55.2 | GPa |

| Compressive Strength | 615 | MPa |

| Flexural Strength | 882 | MPa |

| Flexural Modulus | 60.1 | GPa |

| Interlaminar Shear Strength | 69.8 | MPa |

| Tg Onset (DMA) | 140 | °C |

| Tg Peak (DMA) | 148 | °C |

General Properties

| Gross Weight | 0.73 | kg |

|---|---|---|

| Brand | XPREG |

This prepreg fabric is optimized for autoclave curing, a process that uses controlled heat and pressure to achieve superior consolidation and void-free laminates. The recommended curing cycle typically involves temperatures around 120°C to 180°C and pressures of 6 to 7 bar, depending on the specific resin system. The XC130 prepreg exhibits excellent mechanical properties, including high tensile strength, stiffness, and impact resistance, making it suitable for critical applications such as aerospace panels, racing components, and structural reinforcements. Additionally, its 210 g/m² weight and fine weave pattern ensure a smooth surface finish, reducing the need for extensive post-processing.

Key advantages of the XC130 prepreg carbon fiber fabric include ease of handling, reduced waste, and enhanced precision during layup, as the resin content is pre-measured and evenly distributed. The prepreg format minimizes the risk of resin-rich or fiber-starved areas, ensuring uniform performance across the laminate. With its combination of lightweight construction, outstanding mechanical properties, and compatibility with autoclave curing, the XC130 prepreg carbon fiber fabric is a top-tier choice for engineers and manufacturers seeking to push the boundaries of performance and efficiency.

Here is the technical data for XC130 Prepreg Carbon Fiber Fabric 210g 1250mm width (Autoclave Cure):

Physical Properties:

- Areal Weight: 210 g/m²

- Fabric Width: 1250 mm

- Fiber Type: High-strength carbon fiber

- Weave Pattern: Typically twill or plain weave for smooth finish and flexibility

- Prepreg Resin Content: ~35-42% by weight (varies by manufacturer and application)

- Fabric Thickness: ~0.2-0.3 mm

Curing Parameters (Autoclave Process):

- Curing Temperature Range: 120°C to 180°C (specific to resin system used)

- Curing Pressure: 6 to 7 bar

- Curing Time: Typically 60-120 minutes, depending on curing temperature and laminate thickness

- Post-Cure (Optional): Additional heat cycle to maximize thermal and mechanical properties

Mechanical Properties (Cured Laminate):

- Tensile Strength: ~600-800 MPa

- Tensile Modulus: ~50-70 GPa

- Flexural Strength: ~550-700 MPa

- Flexural Modulus: ~45-65 GPa

- Interlaminar Shear Strength (ILSS): ~40-60 MPa

Key Features:

- Void-Free Laminate: Achieved through autoclave pressure and prepreg resin system

- Surface Finish: Smooth, ideal for visual and structural applications

- Resin System: Typically an epoxy-based system for high performance

-

Storage Requirements:

- Freezer Storage (-18°C): Up to 12 months shelf life

- Room Temperature Work Life: 3-5 days

Applications:

- Aerospace components (panels, structural parts)

- Motorsport parts (bodywork, chassis components)

- High-performance sporting goods

- Industrial tooling and reinforcements

The XC130 prepreg fabric delivers a reliable combination of precision, high mechanical performance, and ease of processing, making it an industry favorite for advanced composite manufacturing.