Prepreg Glass Fibre XC130 280g 2/2 Twill (1270mm). Width

Couldn't load pickup availability

https://www.ebay.co.uk/itm/314715573867

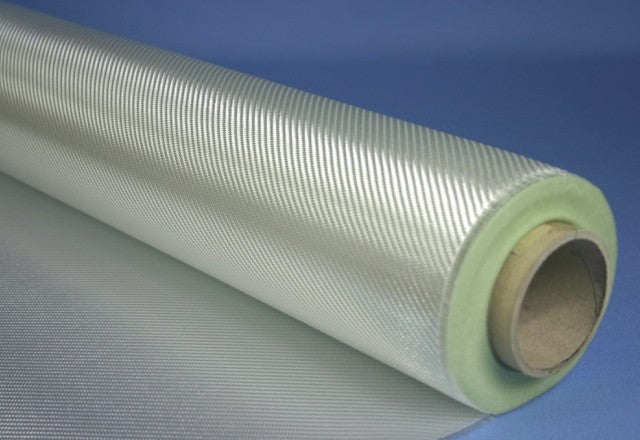

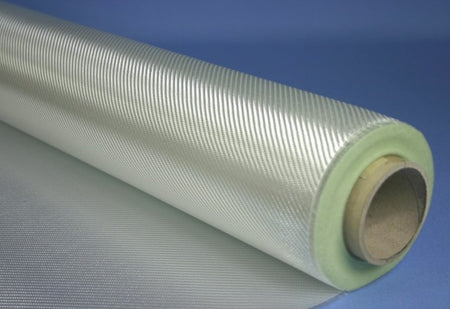

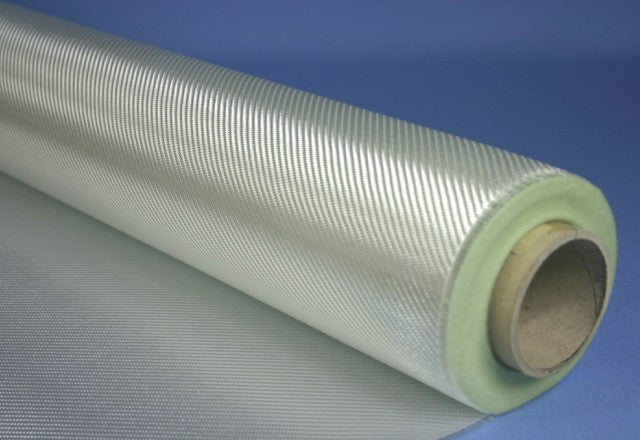

Prepreg Glass Fibre XC130 280g 2/2 Twill (1270mm width) is a high-performance composite fabric that combines the strength and durability of glass fibers with the precision of a prepreg resin system. With an areal weight of 280 g/m², this fabric is suitable for applications requiring robust structural reinforcement. The 2/2 twill weave offers excellent flexibility and drapeability, allowing the fabric to conform to complex shapes during the lamination process. The fabric is pre-impregnated with a resin system, ensuring a consistent resin-to-fiber ratio, which results in reduced processing time and superior laminate quality.

SPECIFICATION

| Ends | 8 | cm |

|---|

Fabric Specification

| Picks | 8 | cm |

|---|---|---|

| Colour | White | |

| Fibre Orientation | 0, 90 | |

| Type | Component Prepreg | |

| Resin Matrix | Epoxy | |

| Weave | 2 x 2 Twill | |

| Format | Woven Fabric | |

| Fibre Type | Glass Fibre |

Typical Laminate Properties

| Tg Onset (DMA) | 140 | °C |

|---|---|---|

| Tg Peak (DMA) | 148 | °C |

Fibre Properties

| UV Resistance | Good | ||||||

|---|---|---|---|---|---|---|---|

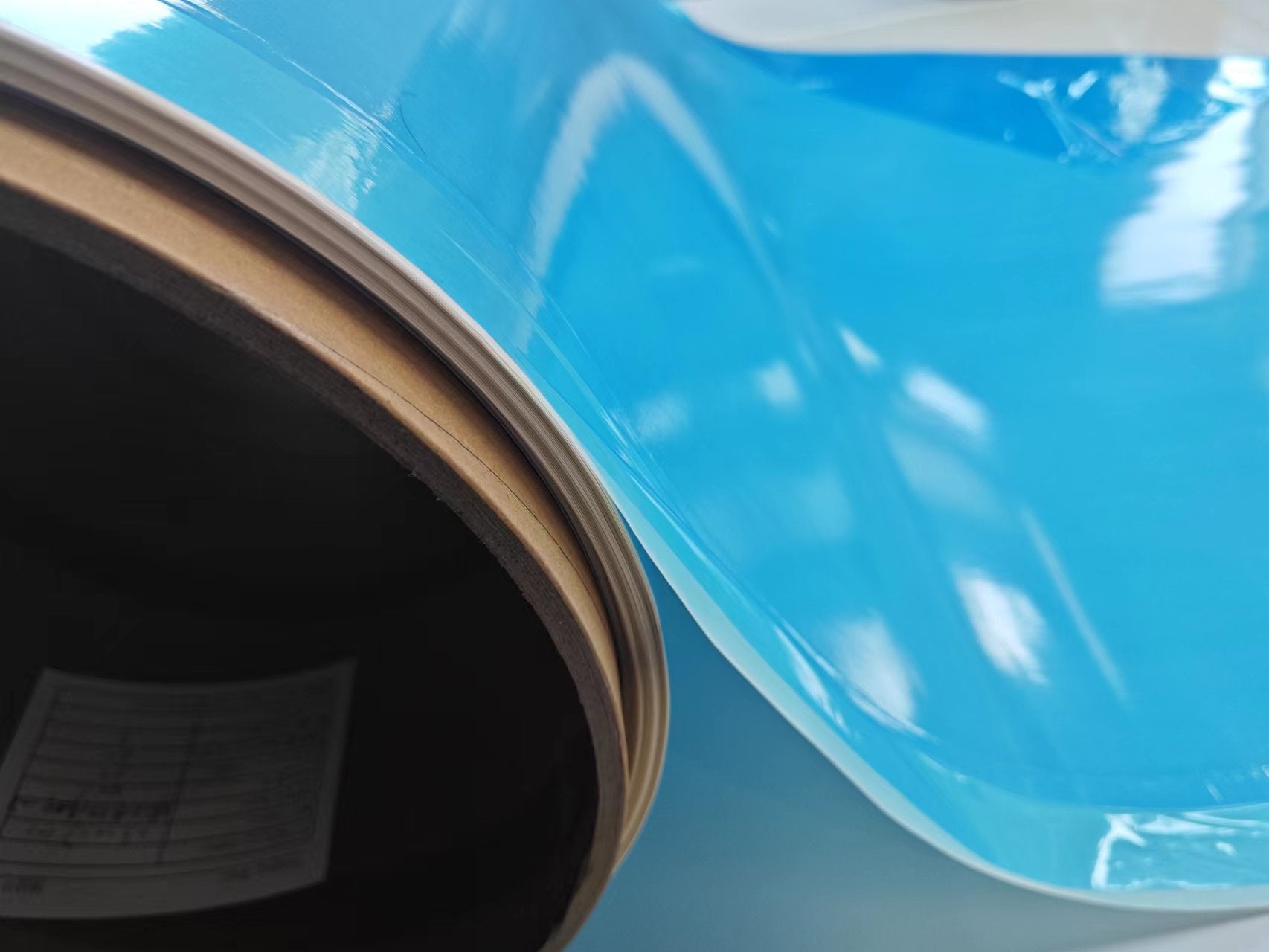

| Freezer-life (at -18°C) | 12 | Months | |||||

| Out-life (at 20°C) | 30 | Days | |||||

| Width | 1270 | mm | |||||

| Min Cure Temp | 80 | °C | |||||

| Max Cure Temp | 120 | °C | |||||

| Max Service Temp | 130 | °C | |||||

| Resin Weight | 38 | % | |||||

| Consolidated Thickness | 0.3 | mm | |||||

| Areal Weight | 280 | g/m²

General Properties

|

This 280 g glass fiber prepreg fabric is designed for advanced composite applications, particularly in industries like aerospace, automotive, and industrial sectors, where strength, lightweight properties, and ease of fabrication are crucial. The 1270mm width provides ample coverage for larger components, minimizing waste during manufacturing. The 2/2 twill weave enhances the material’s overall strength and impact resistance while also offering a smooth, uniform surface finish that reduces the need for extensive post-processing. The prepreg format simplifies the lay-up process, ensuring high-quality laminates with reduced risk of resin-rich or fiber-starved areas.

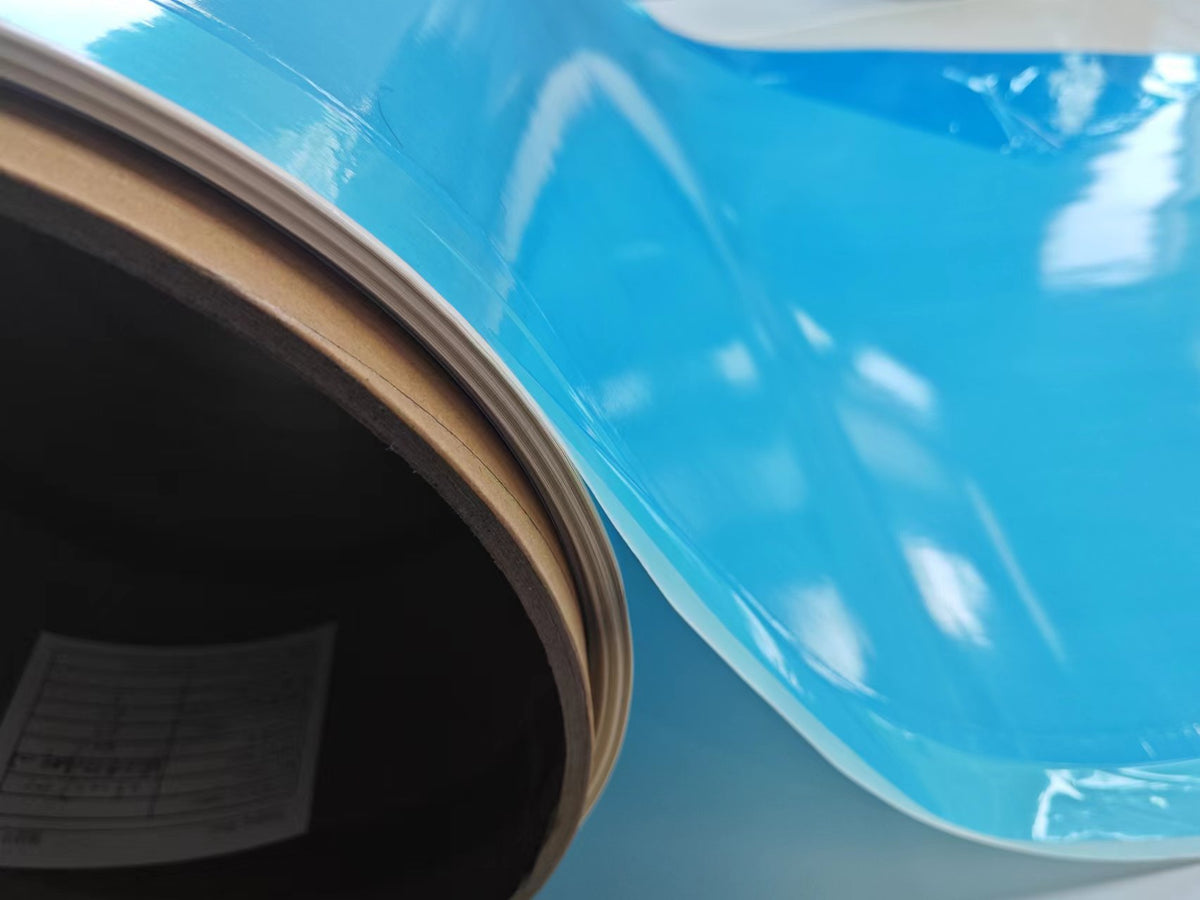

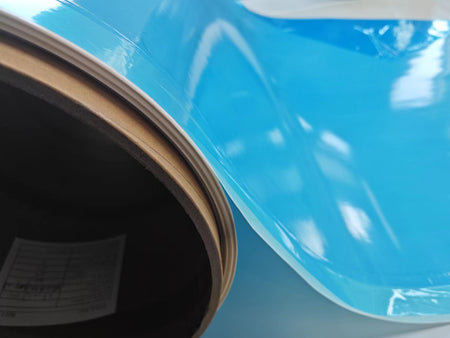

The XC130 prepreg glass fiber fabric is engineered for autoclave curing, a process that uses controlled heat and pressure to achieve a high-quality, void-free laminate. The autoclave process ensures optimal consolidation, leading to improved mechanical properties and overall performance. This fabric is compatible with various resin systems, most commonly epoxy, to meet the requirements of specific end-use applications. Its combination of high strength, excellent drapeability, and ease of handling makes it a top choice for manufacturers looking to produce durable, lightweight composite parts for industries demanding high performance and reliability.

Here is the technical data for Prepreg Glass Fibre XC130 280g 2/2 Twill (1270mm width):

Physical Properties:

- Areal Weight: 280 g/m²

- Fabric Width: 1270 mm (standard width)

- Weave Type: 2/2 Twill (diagonal pattern)

- Fiber Type: High-strength glass fiber

- Resin Content: Typically 35-42% by weight (depending on the specific resin system used)

- Fabric Thickness: ~0.25-0.3 mm (depending on resin content)

Curing Parameters (Autoclave Process):

- Curing Temperature Range: 120°C to 180°C (specific to the resin system used)

- Curing Pressure: 6 to 7 bar

- Curing Time: Typically 60-120 minutes (based on the thickness of the laminate and the resin system)

- Post-Cure (Optional): Additional heat cycle to maximize mechanical properties, typically at 180°C for 1-2 hours

Mechanical Properties (Cured Laminate):

- Tensile Strength: ~500-700 MPa (varies based on curing conditions and resin type)

- Tensile Modulus: ~40-50 GPa

- Flexural Strength: ~450-600 MPa

- Flexural Modulus: ~35-45 GPa

- Interlaminar Shear Strength (ILSS): ~30-50 MPa

Key Features:

- Surface Finish: Smooth finish, ideal for structural and aesthetic applications

- Void-Free Laminate: Achieved via autoclave curing process, ensuring high mechanical performance

- Resin System Compatibility: Compatible with epoxy and other high-performance resin systems

-

Storage Conditions:

- Freezer Storage (-18°C): Recommended for long-term storage (6-12 months shelf life)

- Room Temperature Work Life: ~4-7 days (depending on temperature and humidity)

Applications:

- Aerospace: Structural components, panels, and reinforcements

- Automotive: Lightweight parts and panels

- Industrial: High-performance machinery and tooling

- Sporting Goods: Equipment and accessories requiring high strength and durability

Prepreg Glass Fibre XC130 280g 2/2 Twill (1270mm width) is a versatile and reliable material known for its excellent mechanical properties, smooth finish, and ease of processing. Its compatibility with autoclave curing makes it ideal for producing high-quality composite parts in demanding applications.